Ciprian Flooring - best choice for Hardwood Flooring

Call today for an estimate

(773) 715 9013

(773) 715 9013

contact@ciprianflooring.com

contact@ciprianflooring.com

If you are like most people you probably love the look and charm of real hardwood flooring. For centuries people have used wood floors throughout their homes to add warmth and charm. Hardwood floors never seem to go out of fashion and can add real value to your home.

The manufacturers of pre-finished hardwood floors have dramatically improved the finish, durability and ease of maintenance of hardwood flooring. It is truly amazing today how many new colorations, wood species, and widths are available to homeowners. Besides the common North American hardwoods (such as oak, maple, hickory and ash), many wood flooring manufacturers now offer exotic hardwood species from all around the World. If you are looking for ways to really express your own personal interior decorating tastes with a more unique looking wood floor you need to go see the exotic wood floors offered by many of the hardwood flooring brands.

Factory-finished wood is available in a variety of styles, colors, textures, and grains, and unfinished wood can be customized with an exceptional line of stains and finishes. Additionally, because unfinished wood can be sanded and coated onsite, we can also add unique inlays and medallions to your floor.

Laminate flooring combines natural looking designs with a tough, durable finish and can be used in almost any area of the home. Laminate floors also offer realistic designs and can replicate the characteristics of the popular handscraped hardwood floors.

Laminate flooring is designed to be floated, which means that it should never be nailed or glued to the sub-floor. Glue-less laminate planks are joined together by a specially designed mechanical locking system with no adhesive being required to join the planks. Laminate flooring has become an extremely popular floor covering alternative for many homeowners to the more expensive hardwood floors and stone/ceramic tiles.

The North American Laminate Flooring Association (NALFA) has a Certification Seal for laminate flooring manufacturers. The Seal certifies that the laminate floor has passed a rigorous and demanding series of ANSI tests designed to evaluate its performance, durability, strength, and overall quality of the laminate flooring. Look for it on the manufacturer's sample boards.

The laminated planks are usually fused together in either a one or two step process. In the two-step process several layers are first glued together and then these layers are combined with the remaining materials and than glued and fused into a plank. This method is called High Pressure Laminate (HPL). The other method is where all materials are fused together in one step and this is called Direct Pressure Laminate (DPL).

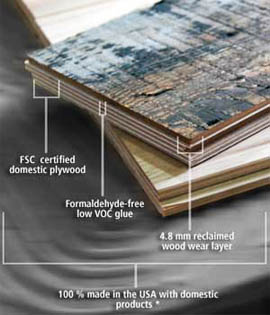

Engineered wood floors are real wood floors made using multiple wood or wood composite veneers. The veneers can be the same or different species. The grain of each veneer runs in different directions, which increases its stability. This means the wood will resist expanding and contracting during fluctuations in humidity and temperature. This type of flooring sometimes can be sanded and refinished, depending on the thickness of its top layer. Engineered wood flooring can be installed above, on or below grade.

Engineered wood floors are constructed differently from solid wood floors and offer some advantages over solid wood floors. Thanks to advancements in manufacturing technology, engineered wood floors can be used in almost any room in the home. This includes installing over dry, concrete slabs and some types of existing flooring. So now homeowners can enjoy the beauty of a real hardwood floor in areas they thought not possible before with solid wood flooring.

Most engineered wood floors are pre-finished at the factory, which eliminates the mess, extra time and vapors associated with applying the finish coats on the job-site. Pre-finished wood floors are ready to be walked on right after the installation is completed. No long waiting for staining and applying coats of finish. Most factory applied finishes are UV-cured with ultra violet lights which creates a much harder finish than a job-site finish. In addition, the manufacturer can apply more coats of finish as well giving added protection.

Installing hardwood on your stairs not only looks elegant, but also lasts much longer than carpet. In fact, while carpeting generally needs to be replaced every 10 to 12 years, hardwood stairs can last a lifetime with proper maintenance, making it an excellent investment. At Ciprian Flooring every hardwood stair installation and refinishing project features expert craftsmanship, quality materials and highly competitive rates.

Whether you're building a home or remodeling, there are several considerations you need to take into account when choosing and building a staircase. These include design, functionality, style and budget. We have the training and experience to take you through every phase of the process, from design consultation to polish, while working within your budget and schedule.

Hardwood is perhaps the most practical of all flooring materials. But over time, the protective finish may wear off, most noticeably in heavy traffic areas. This is the prime reason for refinishing hardwood floors. Applying a modern new finish can even make hardwood floors much easier to maintain than when they were originally installed. Another good reason to refinish your hardwood floor is to freshen up the finish of a wood floor that's dulled from being hidden under carpet for years.

Anyone who's tackled a hardwood refinishing job can tell you it's a mess, starting with the removal of the previous finish. However, we have the knowledge and experience to give your wood floors a quality new finish. We also have the proper equipment to handle the job efficiently, including power sanders to remove the existing finish and to prepare the wood to accept new stain. Unless you have experience in this area, it is not advisable to take on a project of this magnitude by yourself. Even then, the potential cost savings may not outweigh the stress over a job well done.

To determine whether your hardwood flooring's finish is shot or simply dirty, try this simple test. Go to a high-traffic area where the finish takes the most abuse. Pour a tablespoon of water onto the floor. If the water forms beads, the floor is properly sealed. At most, cleaning and stain removal is needed. If the water takes a few minutes to seep in and only darkens the floor slightly, the finish is partially worn. Don't wait too long to refinish the floor. If the water soaks right in and leaves a dark spot, it's definitely time to refinish.

Homeowners tend to procrastinate refinishing hardwood floors because of the dust generated from sanding. Refinishing your hardwood floors can now be a stress-free easy procedure, without the fear and worry of a terrible mess or the toxic fumes. Our guaranteed process uses professional floor sanding equipment and the methods to sand down and clean floors properly, restoring them to their original beauty.

Instead of cloth dust bags - Special hoses connected to the machines evacuates most of the dust created. However, Dustless does not mean no dust, just less. We still use Lägler built Hummel belt sanders, but have added a Trio rotating disk sanders and Cyclone vacuum systems connected to all of our Clark/Alto edgers and Fein hand sanders. Note that the dust bag has been removed from the edger and the edger has a hose attaching it to a Cyclone vacuum system sitting outside. The corners can be scraped anytime after edging and before hand sanding inspected and filling the floor for a second time. Any newly applied filler needs to dry and be sanded with a Fein hand sander, attached to the Cyclone vacuum system.

Floors in overall good condition showing signs of wear and tear often benefit from recoating. To bring worn out floors back to life, we lightly screen or buff your floor, clean it, and finish with one to two fresh coats of polyurethane. A screen and recoat can save you money, labor and time over the life of your hardwood floor.

The phrase “screen and recoat” describes the process of sprucing up an existing coat of polyurethane by top-coating it. (This is sometimes referred to as "buff and coat" because the screen is often driven across the floor by a buffer). But the inclusion of the word ‘screen’ is vital because in order to get a new coat to adhere to the old one you must lightly sand or ‘screen’ it.

Place area rugs, throw rugs or mats in high traffic areas to prevent scratches on your floors. In addition, use floor protectors on the feet of your furniture and be careful when moving furniture around a room. Be conscious of footwear (high heels can scratch and dent wood surfaces) and pets (keep pet nails trimmed to avoid excessive scratching).

EPA studies have shown that indoor pollutant levels can be two to five times higher than they are outside. To find the source of many of these pollutants, just glance down. Installation of new flooring can fill the air with hundreds of volatile organic compounds (VOCs), including known and suspected carcinogens like formaldehyde and benzene. It can take years for these substances to dissipate. There are several sustainable flooring options that can minimize indoor pollution

Environmentally Friendly flooring is any flooring that is sustainable, eco-friendly, contains recycled content, is recyclable, leaves a small carbon footprint or has low VOC’s. There are different degrees of green when referring to different types of flooring.

For home-owners sold on traditional hardwood floors, the Forest Stewardship Council can make sure that your lumber comes from sustainably managed forests. Dozens of types of wood are produced in FSC-certified forests in which the trees are regenerated, biodiversity is conserved, and air and water quality are preserved.

Bamboo, a popular green flooring option, is 13 percent harder than maple and 27 percent harder than northern red oak, so it lasts longer and can withstand more use than conventional hardwood floors. The floors are naturally resistant to water, mildew, and insects, and they are sustainable since bamboo grows quickly and abundantly

(773) 715 9013

(773) 715 9013

contact@ciprianflooring.com

contact@ciprianflooring.com